|

MOUNTING--

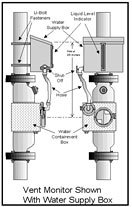

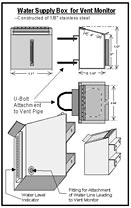

Mount Vent Monitor in vent pipes at a level that permits easy observation of the Sight Glass and easy filling of the Water Supply Box. Mount Water Supply Box on vent pipe above Vent Monitor.

CONNECTING TO A WATER SOURCE--

After mounting, connect the Water Supply Box to the Vent Monitor using the connecting hose. Fill Water Supply Box and allow the Vent Monitor to automatically fill with water to the proper level.

VERIFYING THE PRESENCE OF A WATER BARRIER AGAINST SEWER VAPORS MIGRATING TO THE OUTSIDE ATMOSPHERE--

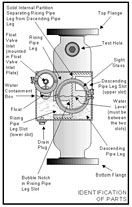

Verifying the integrity of the water seal within the vent pipe can be done by direct observation through the Sight Glass. Look for a water level about in the middle of the Sight Glass, between the Rising and Descending Pipe Leg Slots.

REGULATORY TESTING--

Regulatory testing of the air above the seal, if necessary, can be accomplished by removal of the testing plug.

OBSERVING AIR BEING DRAWN INTO SEWER THROUGH THE VENT MONITOR DURING A LOW PRESSURE EVENT--

When air is drawn into the sewer to avoid vacuum lock (a low-pressure event within the sewer), bubbles can be seen in the Sight Glass, rising up from the Bubble Notch.

HIGH PRESSURE EVENTS AND THE WATER LEVEL AS SEEN THOUGH THE SIGHT GLASS--

A high-pressure event within the sewer system will cause the water level in the sight glass to be pushed down. If the internal pressure rises enough, it will push the water level down low enough to escape out of the Rising Pipe Leg Slot. After the high-pressure event is over, the seal will reform.

GOALS OF THE INSTALLATION--

After installation, the vent pipe will have a water seal to satisfy environmental regulations.

Also, the vent pipe will still operate to easily draw air and avoid vacuum lock conditions during

high flow rates within the sewer system. This capacity to easily draw air will also protect other

seals within the sewer system against being unduly depleted of water by having their water levels

sucked down the drain during low-pressure events. The Vent Monitor will also expel air upon internal

pressure events of a somewhat higher pressure differential, when necessary. The Vent Monitor allows

testing of the air above the seal to be accomplished though the testing hole, making a climb to the

top of the Vent Pipe unnecessary. When the Vent Monitor does allow air into the sewer, it retains the

water forming the seal in the Water Containment Box. No water is sucked out of the Vent Monitor and

down into the sewer. Negative pressure events in the sewer system do not deplete the Vent Monitor of

water. The primary purpose of the Water Supply Box is preventing water depletion over time due to

evaporative loss. The water seal preventing fugitive emissions from migrating from the sewer system

to the atmosphere can at all times be visually verified. The Vent Monitor accomplishes these goals

without "bottlenecking" the vent pipe, thus avoiding any compromise of the engineering specifications

and standards of the sewer system. The total square inch cross-sectional area of the vent pipe

(about 7 square inches for a three-inch pipe, is not diminished anywhere within the Vent Monitor.

HOW THE VENT MONITOR WORKS--

Air, to be drawn into sewer, must first be sucked (pushed) down against the water standing in the Rising Pipe Leg. When the water level in the Rising Pipe Leg is pushed low enough, the air exits out the bottom of the Rising Pipe Leg through the slot and into the Containment Box. As the air enters the Containment Box, it bubbles up in front of the Sight Glass through the water in the Containment Box on its pathway into the upper slot and down the Descending Pipe Leg. In this way the Vent Monitor accomplishes its mission of allowing air easily into the sewer system and preventing vacuum lock. Allowing air into the system requires a very small pressure differential. Sewer vapors, to be expelled from the sewer, must push down the water level in the Containment Box (a large surface area relative to the surface area of the water in the Rising Pipe Leg). When the water level is pushed low enough, sewer gas can escape up the Rising Pipe Leg (through the lower slot). Because of the hydraulic advantage involved, expelling vapor from the sewer system requires somewhat more pressure than drawing air into the system. One desirable feature of the Vent Monitor to note is that only air is sucked down the drain, not water. The water remains in the Containment Box to reform the seal when pressure equilibrium is restored.

SPECIFICATIONS--

The Vent Monitor constructed of 304 stainless steel, with some brass fittings. Three-inch Vent Monitor Dimensions: Height: Approx. 20". Width: Approx. 9". Depth: Approx. 9". Weight: Approx. 43 lb. Four-Inch Vent Monitor Dimensions: Height: Approx. 22". Width: Approx. 11". Depth: Approx. 12". Weight: Approx. 53 lb.

|